ORMOCER® coatings from Fraunhofer ISC

Multifunctional coatings for a wide variety of materials

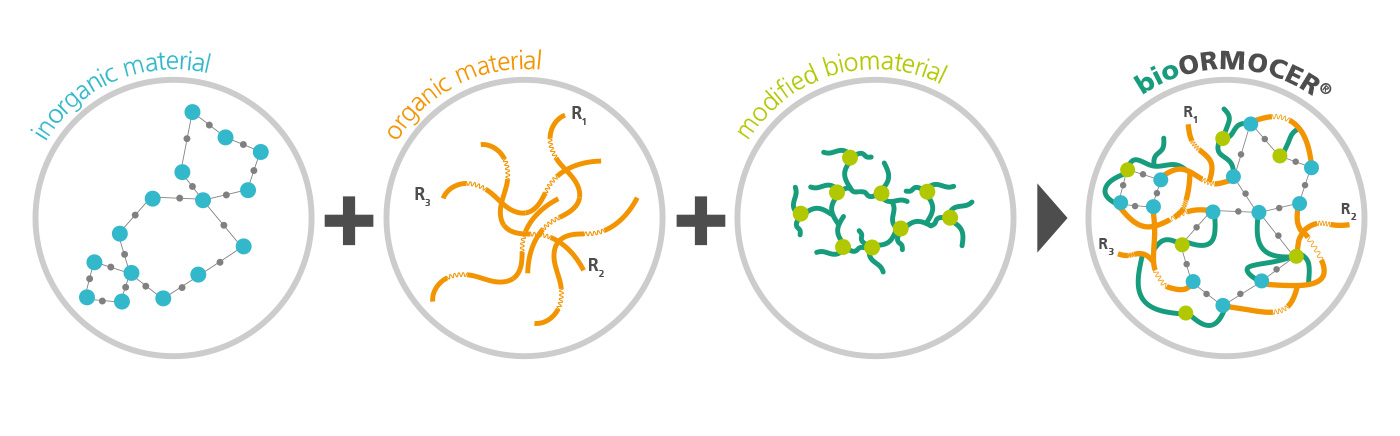

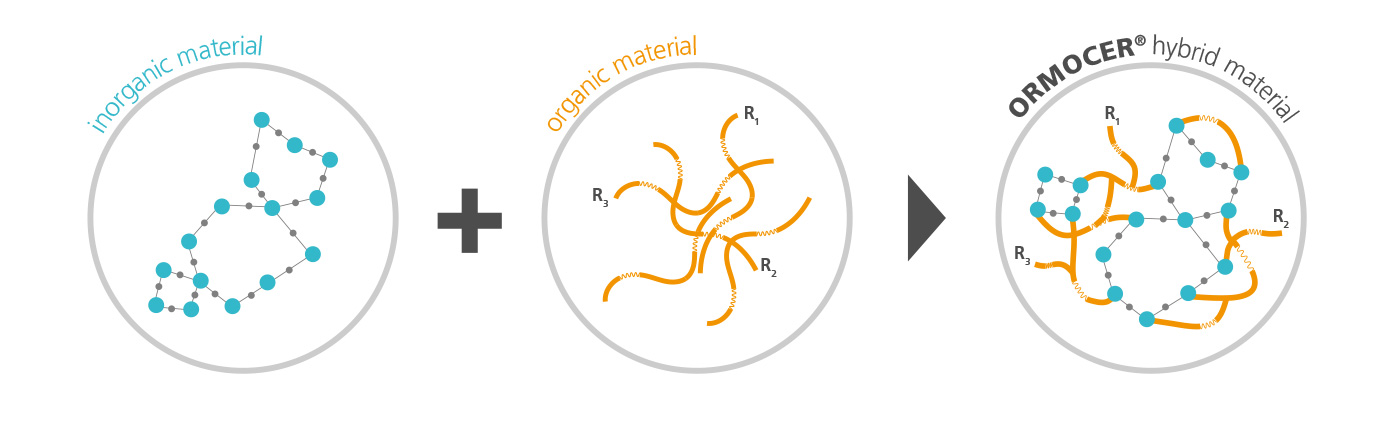

ORMOCER® materials belong to the group of inorganic-organic hybrid materials and were developed at Fraunhofer ISC more than 30 years ago. They are constantly being optimized for many different applications and products, form a own class of materials and are manufactured using the sol-gel process. ORMOCER® materials combine the advantages of inorganic (glass or ceramic-like) and organic (polymer-like) materials in a new, hybrid material.

This allows them to be used, for example, as very resilient but also extremely flexible protective coatings. The scientists at Fraunhofer ISC are thus in a position to offer customized synthesis, as well as functionalization and further processing of the ORMOCER® materials according to customer-specific requirements.

ORMOCER® is not a classical composite material. The individual components are covalently and irreversibly linked to each other. The resulting parallel network formation of an organic and an inorganic network is responsible for the outstanding properties of the materials.

During synthesis (sol-gel process), an inorganic network is built by the targeted hydrolysis and condensation of organically modified silicon alkoxides. In addition, co-condensation with other metal alkoxides (Ti, Zr, Al alkoxides) is possible. Furthermore, the organic groups of the silicon alkoxides can contribute to an organic functionalization of the inorganic network and thus bring additional functions to the material.