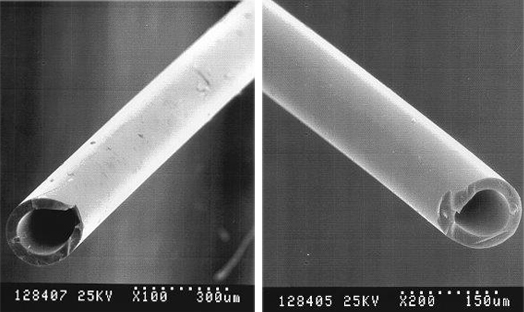

Flexible hollow fibers

A new spinning method allows special, spinnable ORMOCER® to be manufactured into hollow fibers with properties that can be modified according to specific applications.

Wide range of possible sites, modifications and resizing

The properties of the new inorganic-organic hollow fibers range from glass-like and brittle to rubber-like and flexible, and from gas-tight to highly permeable. The outer diameters measure from less than 100 µm up to > 10 mm. Currently, wall thicknesses of between 20 µm and 100 µm are possible. Transparency, good thermal stability and biocompatibility are other characteristics of this type of duroplastic hollow fiber.

Sol-gel technology as a key to spinnability

The key to variability lies in the dual character of the ORMOCER® as inorganic-organic copolymer. The complex rheological preconditions for spinnability are largely created by the sol-gel process (inorganic network), whereas the organic and inorganic segments are available to modify a wide range of properties (e.g. permeability).

A sophisticated concept with few technical requirements

A spinning method based on radiation-induced UV-curing reduces the technical requirements to a minimum. The spinning mass is applied in the form of UV-curable solvent-free resins.

Nanoporous SiO2 hollow fibers derived from ORMOCER® (hollow) fibers

The ORMOCER® hollow fiber is an ideal initial point for purely inorganic silicate hollow fibers. The three-dimensional inorganic Si-O-Si network created within the fiber forms the backbone for the SiO2 hollow fiber.

Pyrolysis causes a tightly constrained distribution of the pore radii in the nm range (0.7 to 3 nm). Apart from a high specific BET surface of up to 700 m2/g and a porosity of up to 60 percent by volume, these fibers also feature good resistance up to 100 MPa and relatively good flexibility.

Application

Possible applications of the new ORMOCER® hollow fibers range from semipermeable membranes for the separation of substances to microcapillaries or tubes with variable mechanical properties that are used solely for transport purposes. One of the most likely applications for nanoporous hollow fibers is in the field of gas separation at elevated temperatures (up to 400°C).